PROCESS AUTOMATION

With the use of the standardized mold loading robot ROBOFLEX you can automate the mold handling in your production process economically, be it for loading and unloading of the mold cleaning equipment or also for the format change on the chocolate production lines. Whether it is a new plant or an existing old plant, whether it is a 1-/2- or 3-track plant, our Roboflex can be adapted to your needs. For new lines the operation is done directly from the touch panel on our mold cleaning line. For new installation on existing plants the operation is done via the separate Roboflex operating panel.

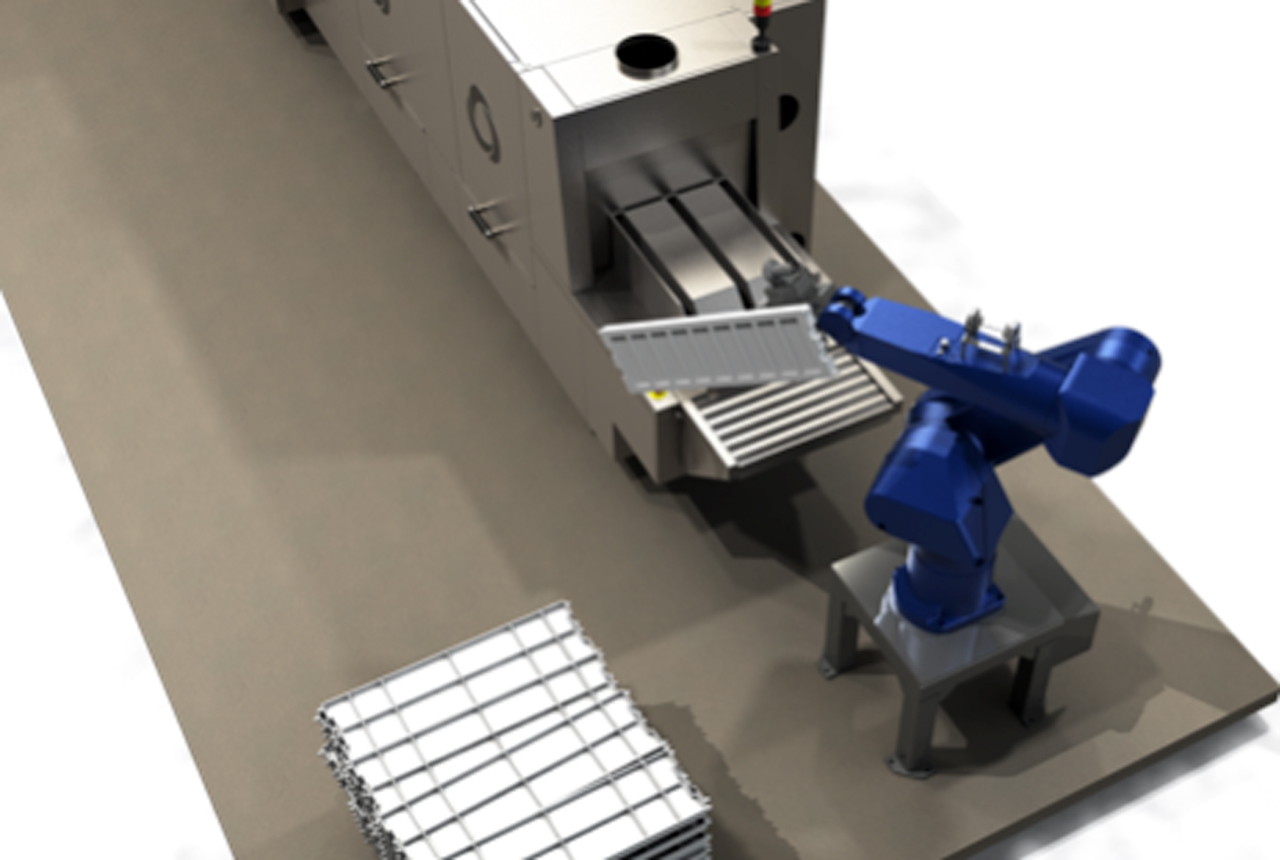

LOADING / UNLOADING WASHING SYSTEM

MOLD CHANGE ON PRODUCTION LINES

FLEXIBILITY

The Roboflex is designed to meet customer specific requirements, whether from pallet/palox or other customer mold storage systems. The gripping head is also adapted to the different customer molds be it vacuum or mechanical clamping gripping head.

ECONOMY – SAVE ENERGY AND MONEY

Automated loading and unloading of your mold cleaning system prevents idle times on the machine as it can always be operated with optimal full capacity. This reduces energy consumption, less water & detergent consumption and constant performance mean significant savings and increased productivity.

THE ROBOFLEX R0 400 STANDARD 6 AXIS MOULD ROBOT SYSTEM

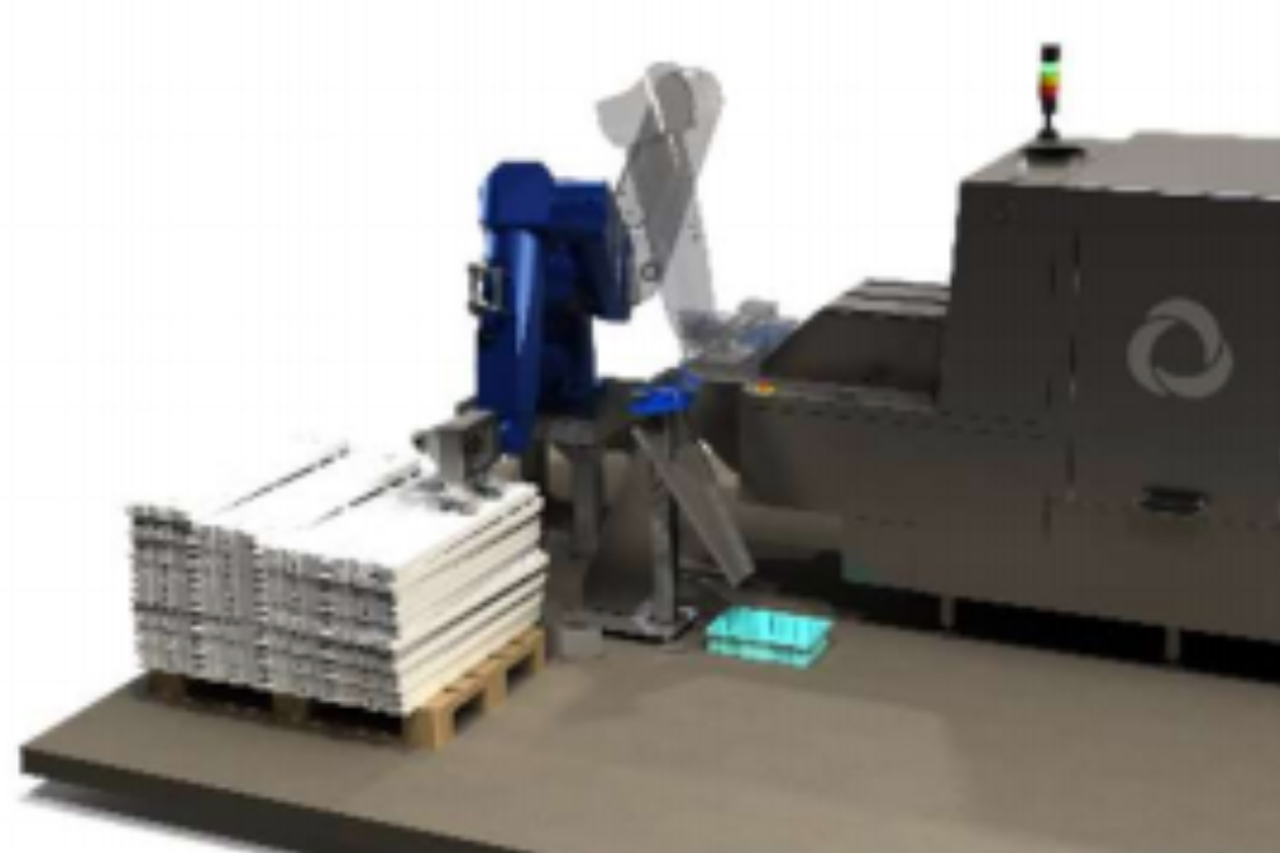

The Roboflex RO 400 offers a standardized 6 axis robot application for loading and unloading of molds from the mold cleaning line or for format changeover on the chocolate production lines from MMS mold carrier , from paloxe, from big box, from customer mold carrier or from pallet. State-of-the-art ROBOTER technology meets the strictest hygiene requirements. The ROBOFLEX system is specially designed to meet the requirements of mold handling in the confectionery industry. Moisture-proof fully enclosed 6-axis robot in hygienic design IP65, load capacity up to 28 kg with a reach of 2010mm allows stacking heights depending on the mold formats up to 1800mm. The spherical working area and the large reach ensure optimal use of the working space. Simple and clever.

PALOXES LID REMOVAL

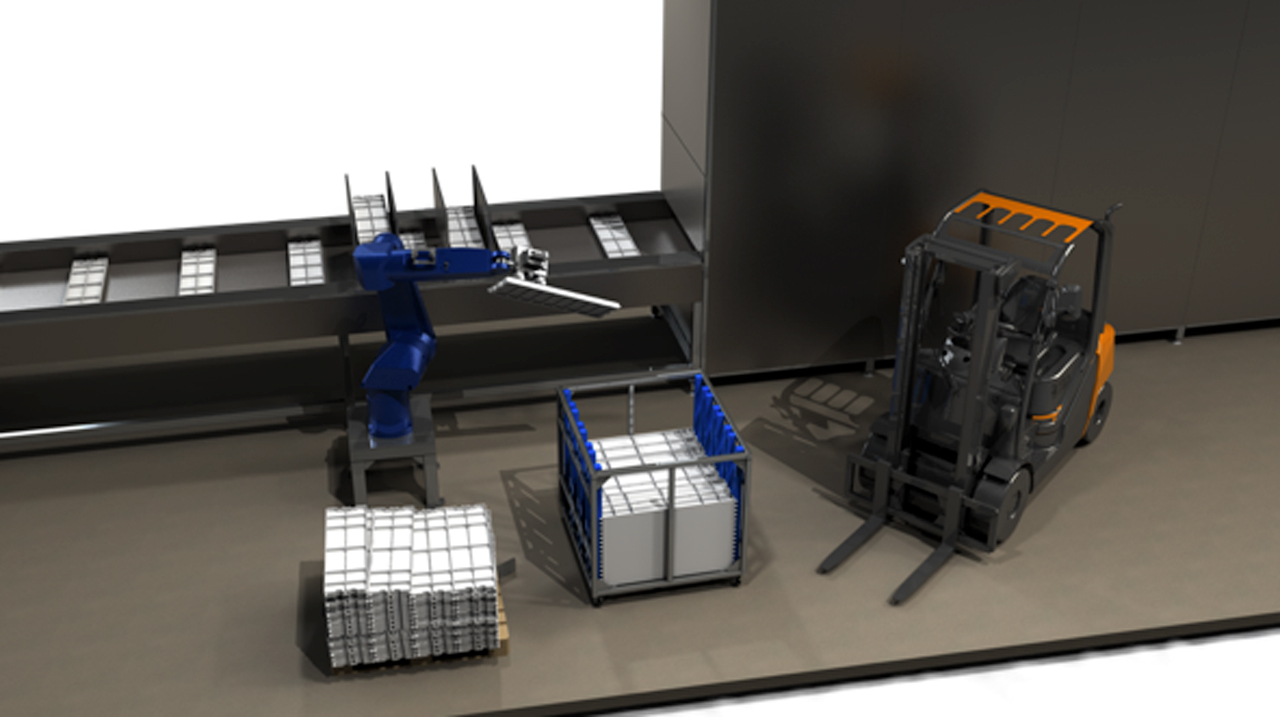

DESTACKING/STACKING IN PALOXES

DESTACKING/STACKING FROM PALLET

PALOXES LID REMOVAL