Chocolate mould cleaning washers

For renowned chocolate manufacturers, mold cleaning is not simply an appendage, but a central point of comprehensive quality assurance. Because only optimal washing and drying results allow efficient production and SPOTLESS products. Hildebrand offers tailor-made solutions – depending on output requirements, and on given situations such as plant size and available space. Hildebrand stands for perfect drying, spotless molds and highest efficiency and availability.

Chocolate mould cleaning washers

Combiflex

Combiflex mold cleaning systems are specially designed for the upright cleaning of chocolate molds. The plants are of modular design and can be individually adapted to the required throughput or mold requirements.

Mould cleaning system

Chocolate molds

Plates & blisters

Boxes & containers

Buckets & barrels

200 – 800 MOLDS/H

MODULAR & COMPACT

TUNNEL SYSTEMS

Your consent is required to display this content from vimeo - Privacy Settings

Chocolate mould cleaning washers

HI830/850

Powerunit with finesse.

This industrial cleaning machine offers maximum flexibility and cleaning quality. The machines are optionally available with automatically liftable hood for an ergonomically optimal operation of the system.

Batch cleaning system

Plates & blisters

Boxes & containers

Buckets & barrels

Baking trays

Parts cleaning

UNIVERSAL

COMPACT

BATCH PLANT

Chocolate mould cleaning washers

MiniJet

This system is suitable for washing, rinsing and drying a wide variety of cleaning goods. Whether containers, molds or parts of chocolate processing plants; the Minijet does a great job, runs efficiently, economically and is characterized by its extremely user-friendly one-person handling.

Batch washer with drying

Chocolate molds

Plates & blisters

Boxes & containers

Parts cleaning

150 MOLDS/H

COMPACT

BATCH SYSTEM

Your consent is required to display this content from vimeo - Privacy Settings

Chocolate mould cleaning washers

Variojet NT

The Variojet system is specially designed to meet the requirements of cleaning chocolate molds and containers. The machine is easy and safe to operate via a touch display. The unit has a large washing, rinsing and drying chamber and is specially designed for optimal cleaning and drying of the washed goods in the washing trolley.

Cabin cleaning system for mold cleaning

Chocolate molds

plates & blisters

Boxes & containers

Pallets

Buckets & barrels

Parts cleaning

MOLD CLEANING

CONTAINERS/PLATES/BUCKETS

200 – 400 MOLDS/H

Your consent is required to display this content from vimeo - Privacy Settings

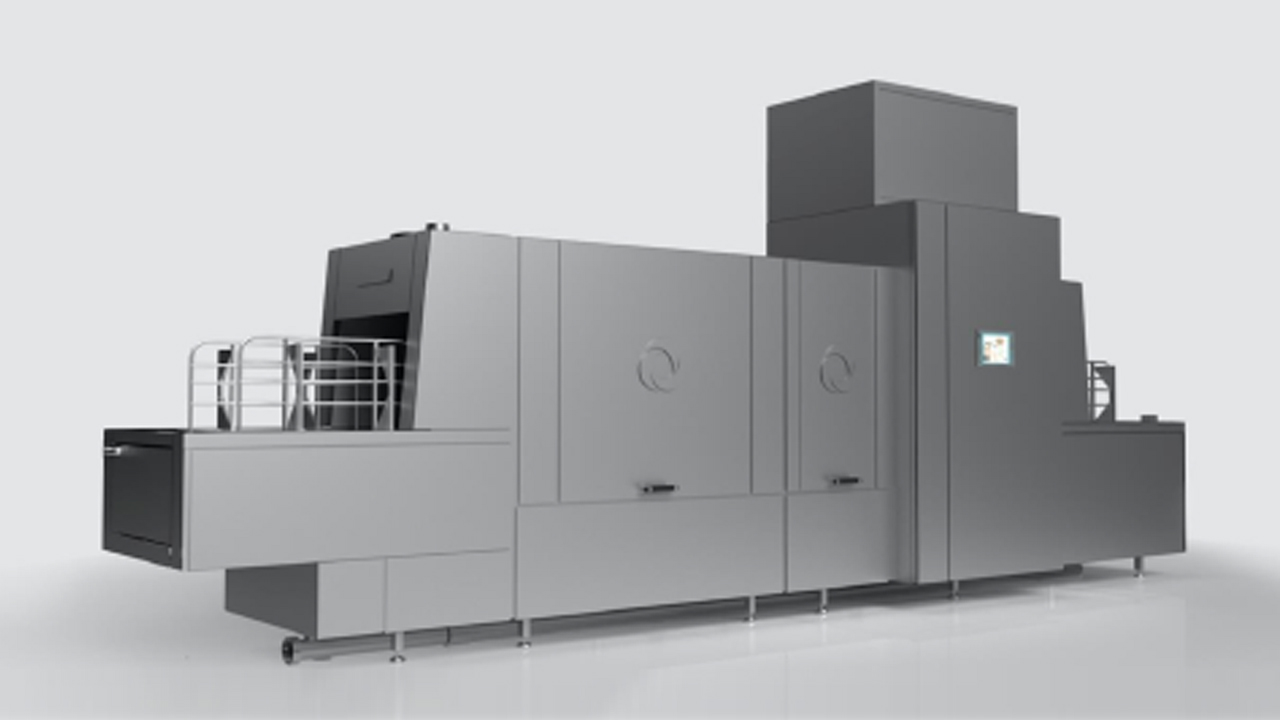

Chocolate mould cleaning washers

Ecoflex 612

State-of-the-art washing technology meets the most stringent hygiene requirements. The Ecoflex system is specially designed to meet the requirements for cleaning containers and/or chocolate molds for the medium capacity range. The machine is easily and safely operated by a HILDEBRAND control system with display. The line has washing, rinsing and drying zones and is specially designed for optimum cleaning and drying of the products to be washed.

Universal tunnel cleaning machines

Chocolate molds

Plates & blisters

Boxes & containers

50 – 500 MOLDS/H

100 – 500 CONTAINERS/H

100 – 500 PLATES/H

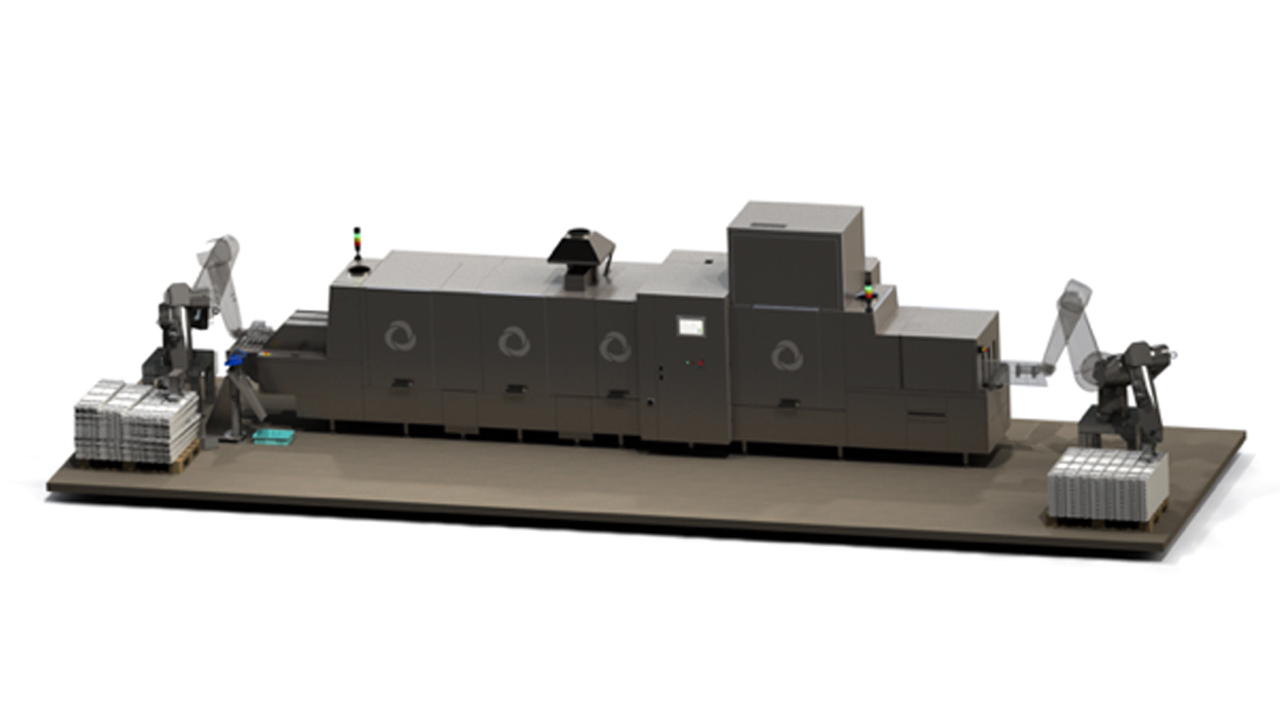

Chocolate mould cleaning washers

roboflex po 200

HILDEBRAND gantry robot automation for existing as well as new mold cleaning lines

Automatic chocolate mold handling Hildebrand can bring You one step forward. With our ROBOFLEX solution, we can bring all types of chocolate molds into your mold washing line in an automated way. No matter whether it is our best-selling COMBIFLEX washing system, or the system from a market competitor. We have a solution. Whether it is a new plant or an existing old plant, whether it is a 1, 2 or 3 track plant, our ROBOFLEX can be adapted to your needs.

Robot automation for mold cleaning lines

Chocolate molds

Boxes & containers

200 – 400 MOLDS/H

1-3 LANE LINES

FULLY AUTOMATIC

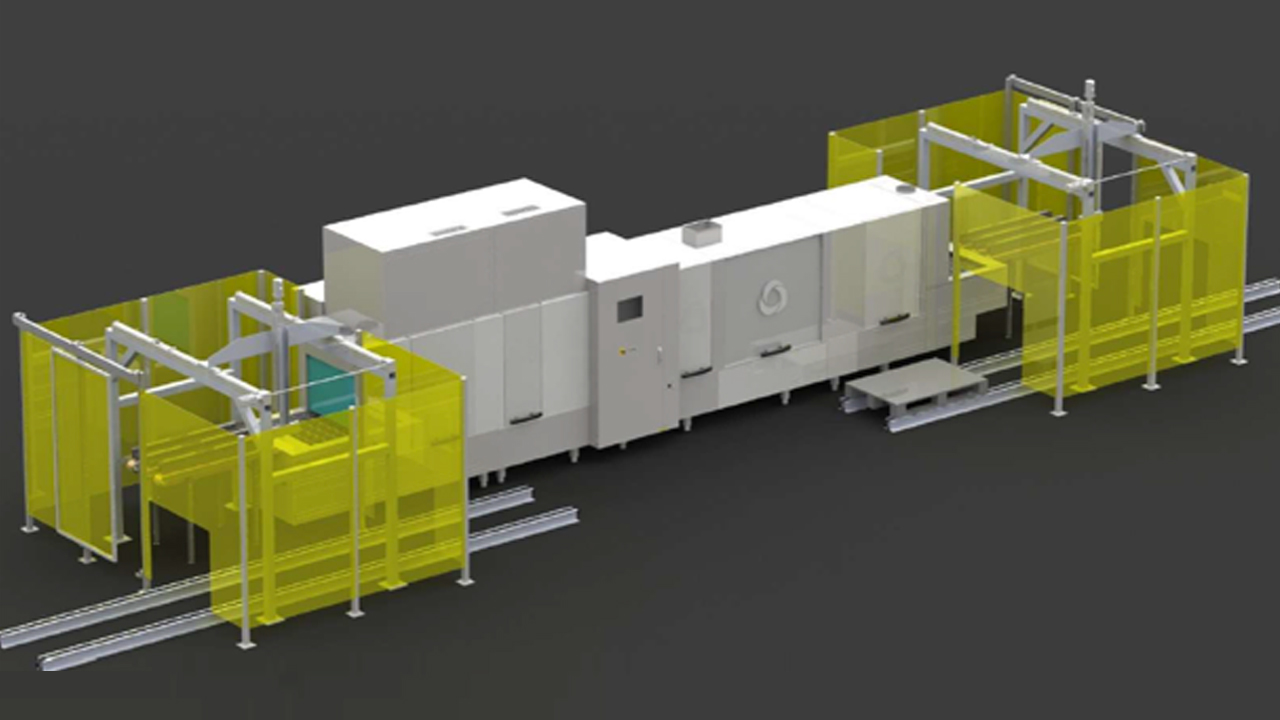

Chocolate mould cleaning washers

roboflex ro 400

HILDEBRAND 6-axis mold robot automation for existing as well as new mold cleaning lines or format change on chocolate production lines.

The existing mold cleaning line is equipped with a 6-axis mold robot system on the infeed and/or outfeed side. The molds are fed to the loading station on pallets or mold storage carriers. The robot detects stack height and mold type via camera. The top mold is automatically picked up and rotated 90° and placed upright on the belt of the free mold cleaning track. The robot’s working area is monitored electronically and the robot stops as soon as a person enters the danger zone. Thus, no barrier fences are necessary and the area is freely accessible. Depending on the mold size and type, standard gripper systems are available that cover most commercially available mold geometries without the need for retooling.

Robot automation for mold cleaning systems

Chocolate molds

Boxes & containers

6 AXES MOLD ROBOT

LASER/CAMERA MOLD RECOGNITION

FULLY AUTOMATIC