ABSOLUTELY TROUBLE-FREE

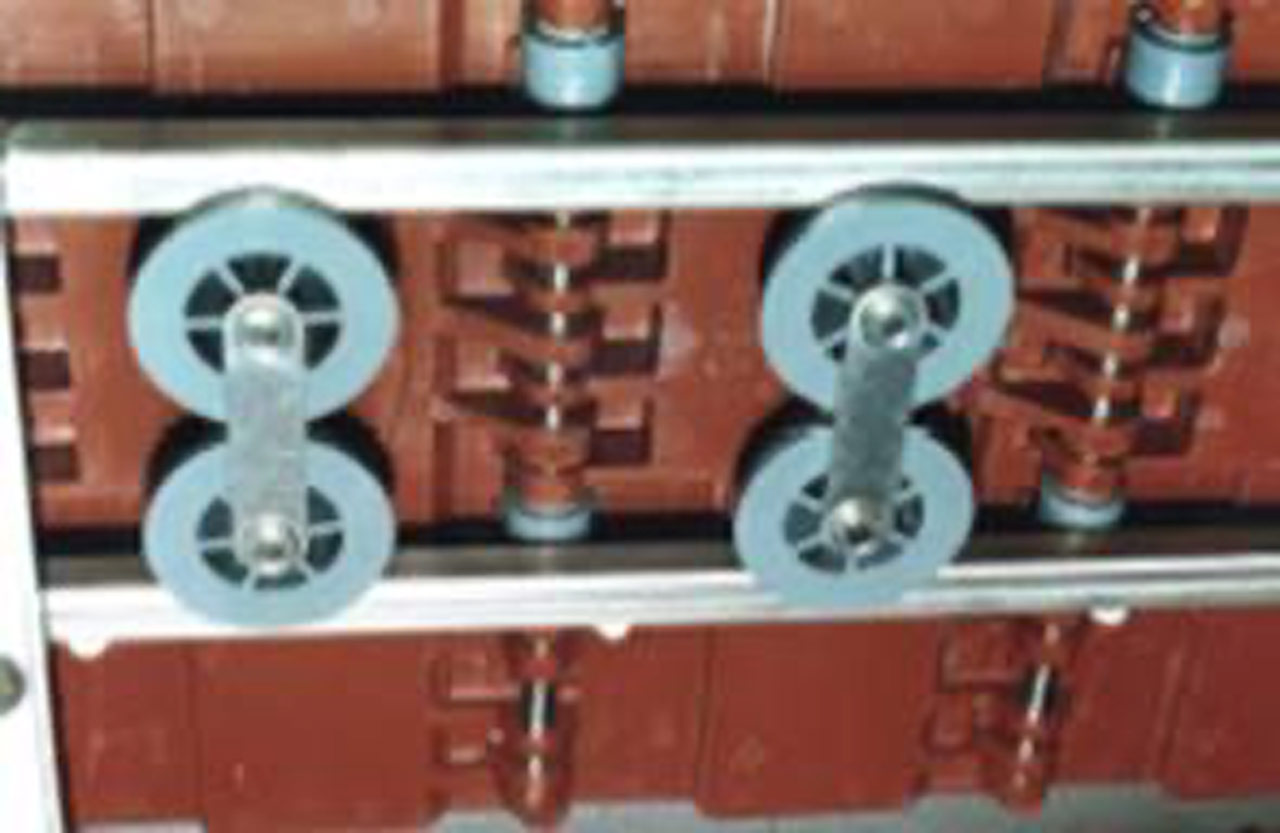

High availability & reliability as no belt transitions, no sensors and no interfaces are necessary. Belt with roller guide and therefore hardly any friction or wear. Even stacked dishes are transported without interruption Hildebrand therefore offers 5 years full warranty on the HR-4 belt.

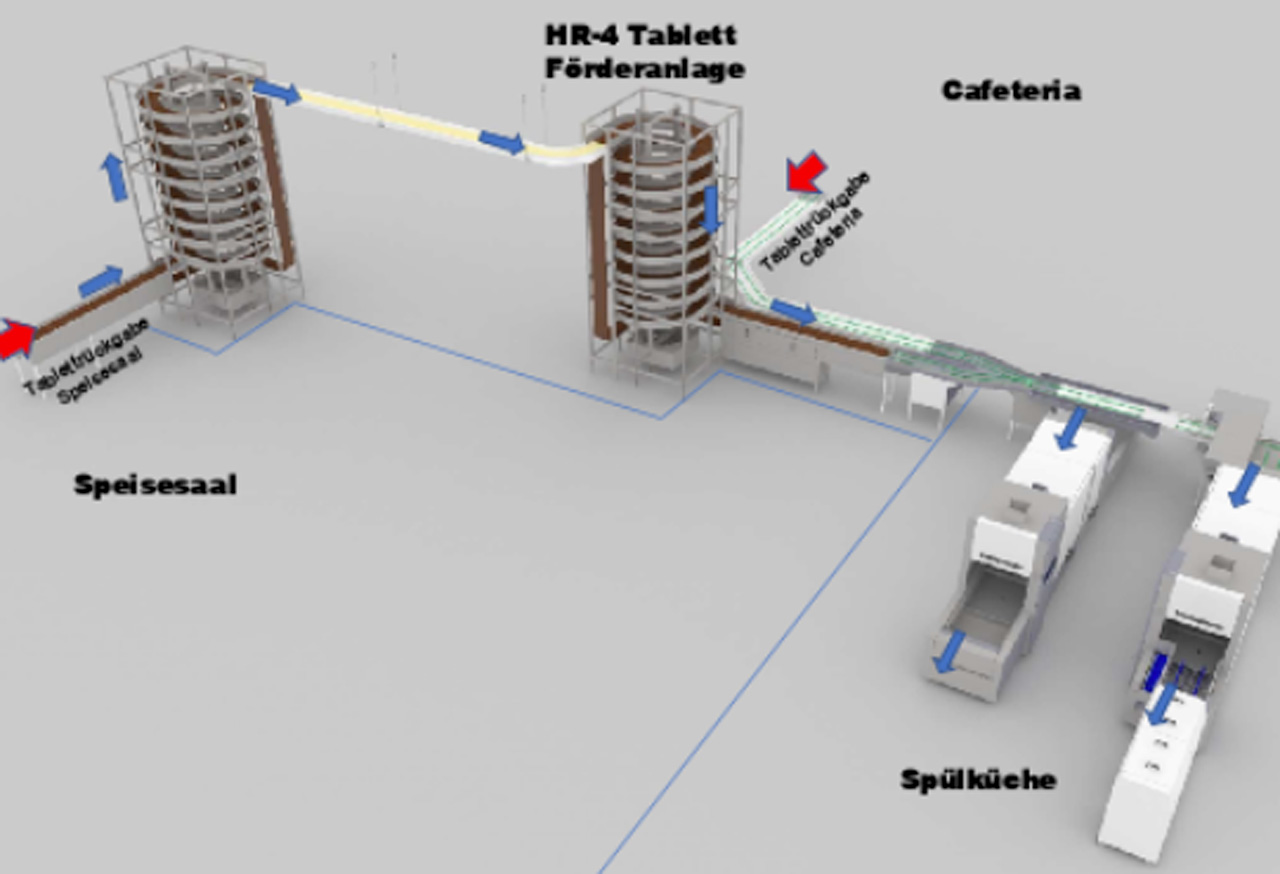

WE BUILD TECHNICALLY ADVANCED, ECONOMICAL AND RELIABLE TABLEWARE CONVEYING SYSTEMS/LOGISTICS SOLUTIONS AND SEE OURSELVES AS A COMPETENT TOTAL SOLUTION PROVIDER.

ADVANTAGES WITH THE HR-4 SHINGLED BELT

1. All-round moving plastic double link plates, which interlock like scales and are connected by CNS axles. The plastic support and guide rollers ensure easy running, generous mobility and reliable guidance in all directions.

2. Very low and constant frictional resistance, thanks to rollers.

3. Forward and backward deflection possible, thus more flexibility and planning integration possibilities, e.g. portioned food forward – dirty dishes backward.

4. Belt separation at standstill possible at any time. The slats can be separated without tools.

5. Endless – belt conveying independent of conveyor length.

6. Endless design allows transport of stacked dishes as there are no belt transitions.

7. Endless belt is infinitely variable from 3.0 – 24.0 m/min.

8. Endless conveying allows absolutely jerk-free operation during braking as well as start-up. Drives are electronically controlled and coordinated among each other. Excellent stability of all dishes. Standing bottles and glasses with residual contents do not spill.

9. Simple adjustment of all drives, which are electronically controlled among themselves depending on load.

10. Operational failure of one drive does not cause a standstill of the shingle conveyor or the transport system.

11. Optimum hygiene, since the endless shingled belt can be washed, rinsed and dried daily in the integrated belt washing and blowing station.

16. 9% incline results in a headroom of 300 mm in the bowl feeder tower.